cotton picking machine mechanism

There are two types of pickers in use today. Others tried mechanical fingers or prongs to remove the cotton lint fibers to be spun into cloth.

Cotton Harvester Machine Britannica

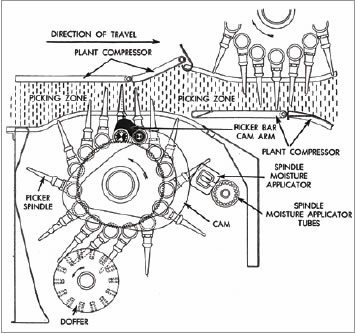

Bar cams and cam tracks cause spindles to enter a cotton.

. The cotton picking head includes upper and lower vacuum compartments both in fluid communication with the vacuum pump and connecting. Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode. The cotton picking machine dramatically increases the cotton - picking efficiency.

A cotton picking machine comprises a chassis for moving the machine in a traveling direction a vacuum pump provided to create a predetermined vacuum and a cotton picking unit including a cotton picking head supported by the chassis. To move the cotton from the doffing area to storage container. The reason is that conventional end-effectors are not suitable for handling cotton sheets.

The development of the mechanical cotton picker goes back to the early 1930s and its proliferation and improvement in the decades that followed made for significantly easier harvesting of cotton. No longer would farmers have to rely on laborers to go out and work the fields all day picking cotton off the bollsinstead they could invest in a cotton picker that. It is equipped with a bigger hopper which can extend the picking time greatly and boast large capacity in the field.

Others tried static electricity. I An arrangement for guiding the plants into the picking zone and providing necessary support while the seed cotton is being removed. Our firm specializes in providing an excellent range of Cotton Picking Machines.

DC12v - Electric Motor. It has a super long time continuous working capacity. Working Principle of Projectile Weaving Machine.

Cotton picking machines have spindles that separate the seed cotton from the burrs which are attached to the stems of each plant. Ii Devices to remove the cotton from open bolls. It has a lasting service life.

The current cotton picker is a self-propelled machine that removes cotton lint and seed seed-cotton from the plant at up to six rows at a time. Cotton harvester harvester cotton picking machine. The cotton picking machine dramatically increases the cotton - picking efficiency.

One is the stripper picker primarily found in use in Texas. Machine has the capability and the economic value for fulfilling the needs of farmers having small land holdings less than 2 acres. Current production pickers have a top-to-bottom spindle contact area of about 30 inches using 18 or 20 spindles per bar.

The performance for the machine is stable and reliable. This application led February 23 1928. Offering Cotton Picking Machine Battery Operated - Voltage.

This picking machine is manufactured with quality tested material and advanc. Drum with a variety of plant sizes and cotton conditions. The front drum of the row unit harvests about 75 of the cotton.

Early on some mechanical engineers tried to pick the cotton with pneumatic mechanisms that acted like giant vacuum cleaners. 11 Need of harvesting machine In conventional harvesting process the. At that point a mechanism called a doffer removes the seed cotton from the aforementioned spindles and directs the seed cotton on to a conveyor system.

Introduction of Cotton Picking Machine. They are also found in Arkansas. As mention earlier in introduction traditional cotton harvesting can be replace using cotton harvesting robots based on machine vision.

The cotton is blown through the discharge duct against cleaning grate in the storage basket lid. Weft is withdrawn from the package through a tension device weft tensioner shuttle feeder scissor and weft end gripper. The picking arm has released the projectile which is shown in the guide teeth at the mid-shed position.

He said that 80 of the Gujarat farmers grow cotton. COTTON FLOWER PICKING MACHINE CFPM Cotton is one of the most important fiber and cash crop of India and plays a dominant role in the industrial and agricultural economy of the country. V797 is the type of cotton grown in this area.

During the time of picking the cotton many faced labour shortage. The cotton picking head includes upper and lower vacuum compartments both in fluid communication with the vacuum pump and connecting. Spindles are spaced 1625 inches along the bar.

At the receiving side the weft end gripper is positioned to grip the weft after reception. CLEANING MACHINE MACHINE FOR MACHINING THE COTS OF COTTON TYPE SQUARE CROPS containing a frame mounted on the head of the machine frame having a rear face with respect to the direction of movement of the machine a hinged body of the hub. The authors have studied a method of picking up a sheet of cotton cloth using a brush.

Following are the basic components of a mechanical picker. Many cotton pickers have been devised and some of these have the. High and new technologies are widely used in the self.

There have already been methods of automating the manipulation of cloth products but their gripping method cannot be basically applied to pick up a cotton sheet. He built a workshop on his own to develop and experiment on his machine. Others tried to adapt grain threshing machines to cotton.

Even farmers their families would join the labourers to pluck the cotton. Features - Cotton Picking. This invention relates to cotton pickers.

Cotton Picking Machine is an innovative Cotton harvesting tool for the Indian Farmers. This action removes some of the trash from the seed cotton. Machine with dual picking unit have 2 separate elevating systems to provide more uniform and positive conveying from each unit.

Apparatus with the formation between them in a vertical plane parallel to the direction of. Classification Of Picking Mechanism Loom Weaving Loom Shuttle Loom Cotton picking machine is designed for cotton picking it can fulfill the cotton-picking operation in 6610cm or 688cm width of cotton planting mode. Using the Cotton picking machine the speed is increased from 50 to 200 as compared to manual picking efficiency.

A cotton picking machine comprises a chassis for moving the machine in a traveling direction a vacuum pump provided to create a predetermined vacuum and a cotton picking unit including a cotton picking head supported by the chassis. This machine is cost effective and easy to maintain and repair for the farmer.

Secondary Motions Of Loom Weaving Machine Loom Loom Weaving

Selection Of Cotton Harvesting Mechanism Results And Discussion Circular Economy For The Management Of Operations

Jacquard Shedding Mechanism Card Pattern Card Patterns Kinds Of Fabric

Beating Mechanism With Sley Loom Weaving Weaving Loom

Eli Whitney Cotton Gin Patent Drawing By Dan Sproul Patent Drawing Eli Whitney Patent Prints

Picking Mechanism On Projectile Weaving Machine Weaving Machine Weaving Industrial Fabric

Positive Tappet Shedding Mechanism Positive And Negative Positivity Negativity

How Do We Pick Cotton Version 2 Baler Pickers Youtube

Mushroom Picking Purple Violet Watercolour All Over Print Clock By Grumblebeeart Printed Clocks Clock Mushroom Pick

Cotton Picking Machine The Portal To Texas History

The Determination Of Variety Effect Of A Simple Cotton Picking Machine On Design Parameters Scialert Responsive Version

International Harvester Cotton Harvesters Octane Press

Fm E 2 Lesson 18 Cotton Pickers Construction And Working Principles

How Do Cotton Harvesting Machines Work

5 Wheel Take Up Mechanism 5th Wheels Weaving Machine Weaving

Beat Up Mechanism In Weaving Weaving Shuttle Loom Motion